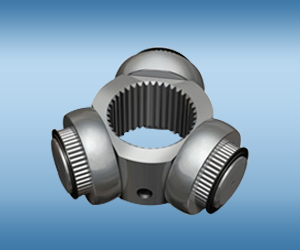

Tripot Joint / Tripod Ball – CV Joint

Hartford Technologies’ bearing specialists collaborate with prominent automotive and off-road vehicle Tier 1 companies to design and manufacture production volumes of tripot joint components.

A tripot ball CV (constant velocity) joint is used at the inboard end of a driveshaft or halfshaft.

It transfers uniform torque and constant speed, despite changes in angle, enabling consistent transmission of power. A tripot joint assembly has needle bearing-shaped rollers that are mounted to a three-part yoke. These fit inside a cup with matching grooves, which attach to the differential. The rollers are mounted at 120° to one another and slide back and forth on tracks inside a housing. A typical tripot CV joint has up to 50 mm of plunge travel, and 26° of angular articulation.

Hartford Technologies has an efficient and cost-effective manufacturing process, unique to the industry, for these critical components. A blank is cut from 52100 (GCr15) high carbon, chromium-containing alloy steel tube, then ground to specified OD, ID and width. Tolerances are typically tight (+/- .0001 for diameters and widths) because a set of rollers fits into the ID, and the OD rides in the cup with the matching grooves.

Finished parts are hardened to Rockwell C 60-65 for superior crush strength and high ductility. Tripot CV joint parts are then polished to a high surface finish. Hartford Technologies manufactures tripot CV joint components in numerous sizes typically within the range of 1” to 4” OD.