Hartford Technologies now offering CorrTech Steel™ as a TrimRite®* alternative (UNS42010) for Balls and Rolling Elements

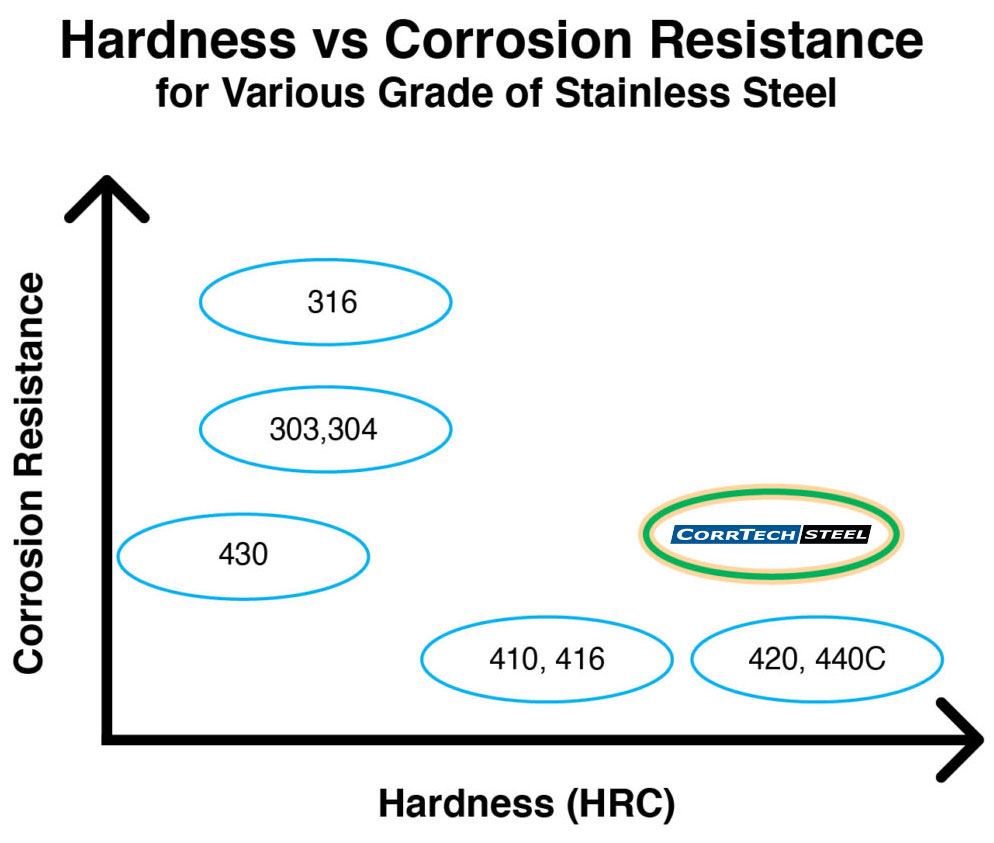

USN42010 is a fully martensitic stainless steel and is hardenable to ~52HRC. It can be used in any application where good strength and excellent corrosion resistance is important. Perhaps the most common ball applications are animal water delivery systems. CorrTech stainless is formulated to be fully martensitic in the hardened condition and is magnetic in all conditions.

Chemistry of CorrTech Steel (UNS42010):

Composition-

Carbon: 0.15/0.30%

Manganese 1.0%

Phosphorous: 0.04%

Sulfur: 0.03%

Silicon 1%

Nickel: 0.25-1%

Chromium: 13.5-15%

Molybdenum: 0.4-1.0%

Iron: Balance

Industry Testing for CorrTech Steel

The industry testing has shown CorrTech stainless to have better corrosion resistance than Types 410, 420 and 440 in a number of environments. It has good resistance to rusting and corrosion by atmospheric conditions and various chloride-containing environments.

CorrTech can be cold worked, hot worked, drilled, machined and heat treated using the same methods as 410 stainless steel.

Suitable application environments include dilute nitric acid, seawater/salt spray, high humidity and sodium hydroxide. The alloy has good resistance to mild atmospheres, mild chemicals, most foodstuffs and many petroleum products. All elements of bearings (balls, rollers, races) operating in these environments can be made completely from CorrTech.

Applications:

- Medical and surgical applications

- Fasteners

- Cutlery and food processing equipment

- Valves

For maximum corrosion resistance parts must be free of scale, foreign particles, free iron and surface imperfections which can trap foreign material and contribute to pitting and crevice corrosion, especially in the presence of chlorides. The presence of any of these conditions will decrease the resistance to rusting in accelerated corrosion tests. Finished parts should be passivated. For more information about CorrTech Steel, we invite you to contact us today.

*Trimrite is a registered trademark of Carpenter Technology