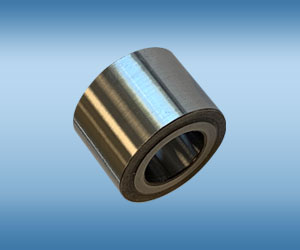

Engine Bearings

Hartford Technologies bearing specialists work with internal combustion engine manufacturers to provide the highest quality engine bearings and rolling elements in the industry.

These bearings can be used with a full complement of needle rollers or as cam followers with a single shaft through their inside diameter.

These bearings are fabricated using the highest quality bearing steel and are built to last hundreds of millions of cycles without any noticeable wear. Our heat treat process is also guaranteed to through-harden the steel to yield a 100% martensitic microstructure with zero retained austenite. Our grinding operations have been refined to yield an ultra-smooth superfinish.

And perhaps the most important feature of the bearing is the geometry that is ground into the surface. It is imperative that the stress is not concentrated at the ends of the bearing. If a bearing has concentrated loading on its ends that will create a stress concentration and lead to premature failure. Our grinding and superfinish operations can grind a crown feature such that loading is deliberately focused in the center of the bearing. Ultra-precision bearings might require a logarithmic profile along the bearing surface so that the loading is distributed more specifically through the entire profile. As the linear distance increases as you move from the center of the bearing toward each end, there is a miniscule logarithmic drop in the bearing profile. We can hold that profile tolerance to 0.005mm